Long Way To A Full Stop. ——inspection And Loading Site Of Welding Rod Packing Line

On 27th April, the inspector arrived at the high speed railway station. In order to save time, our team returned directly to the factory after picking her up. The welding electrode packaging line had already been set up in advance for preparation, and the required welding rods, cartons and PE perforated film were also ready. When the inspector arrived, she saw the welding rod packaging line all set up to simulate the working scene.

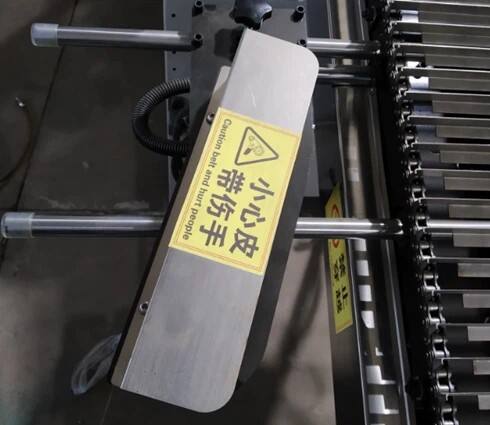

After briefly understanding the name and function of each part, the inspector decided to carry out a test run. After checking the connections and initial settings of each part, FFI operators switched it on, then the packing line slowly started up. The welding rods inside the hopper were brought out smoothly by the chain and lifted into the counting & packing machine.

"In order to facilitate packaging, each batch of welding rods will be organised before being erected, so that the workers can put on the carton easily" Engineer introduced. The automatic packaging line is meant to improve efficiency, so the details of human-machine interaction become the key.

Cartoning is followed by direction transporting, weight-rechecking and rejecting, sealing and cutting, heat shrinking, and stacking.

By adjusting the parameters of the PE film, it is possible to regulate the effect and size of the sealing and cutting.

"Is all this debugging easy? How does the customer master it?" The inspector nodded after watching the whole process and asked a new question.

"We'll provide an operator's manual, with pictures and video instructions if needed." The FFI team has rich service experience and is clearly familiar with this issue, "A technician is required to make adjustments on the customer's side, but we will give help and guidance. The commissioning process is simplified, so don't worry."

The first day's commissioning was very satisfactory, and the second day's cabinet loading was even more straightforward.

Due to the special nature of the equipment and the conditions of shipping the whole container by sea, no wooden cases are involved, winding film + foam film to protect the key screens instead, and reinforced tape and wooden cubes are used to reinforce in the container.

The inspector felt a bit surprised about this kind of packaging and asked why we didn't use wooden cases.

"Routinely if it's a small device or LCL, we use wooden case then." FFI team replied, "But we usually ship whole containers, with safety as the premise, we need to consider the customer's transport costs."

The inspector looked at the irregularly shaped equipment in front of her and nodded. If they were packed in wooden cases, even the 40HQ cabinet type could not hold several pieces.

The whole process of inspection and container loading was completed on the morning of 29th April. The inspector compiled the information and sent it to the customer, and after lunch, set off on the high-speed train, that is the end of the journey.

Now back to the beginning question, what is the end of a contract?

Different people have different understanding and answer. But for FFI, the answer is obvious. Receipt of payment is not, completion of production is not, completion of inspection is not, completion of container loading is not, then, where?

Industrial machines, what we call a long shot, the warranty of which may be one year, but the actual service life of the equipment may be up to ten years, twenty years or more, the after-sales service can never leave the table on half. Only professional service and responsible attitude can cross the time and space, we always stand in the customer's shoes, this is the answer of FFI.

EN

EN