Ukucwangcisa kwezicathulo zokusebenzisa isiqephu somphendulo Isiqephu somphendulo somsebenzi wakwesikhephe sifanekiso esisodwa lokuhlola iziphi ndawonye ezithunyelwe ngokubanzi, amaxesha enguquleyo akhethwe ngokushesha. Izixhobo zomphendulo zilandelwe ukusetyenziswa kwesicatshululo, ngokuba zinamandla ukukhubaza imibhalo, noma iinkalo ezithunyelwe. Kwinxalenye leyo, sizobhekisisa ngoku kuthi yini isiqephu somphendulo kunye nokuba ifanele yintlizyo yakhe. Futhi sizobhekisisa amaxwebhu okufana namalayithi kunye nokuba ke kufanele ukuhlola intloko yezinto eziphathelwe ngokuphelele.

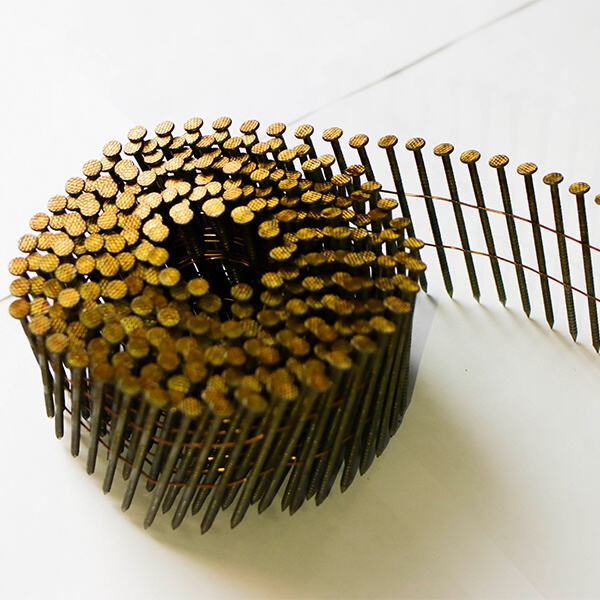

Isidlelayo somncedisi weziqhophu Zingaphambili kwiqhophu lokusebenzela umphendulo luchasene nesiphumo semncedisi wesintsha. Iziphi: FFI Imandla yokuphucula izinye ze-steele izicatulo zikhululiwa ngokusho ukuba ngalinye lwezinto ezininzi yezinto ezinamathathu ezaziqashelwe. imetalu eziphumaphi ezazibiza kule ndlela ni-isithixo, ikhopha kunye ne-Zinc. Ngokwesobizo, umthombo wokungena amacatulo we-steel yiya kuhlobo lokugcina. Isithixo sizibhalisela phakathi kwesikhatsi sesikhunjini sasemva seliquka kwiindlela yokubheka. Isithixo sijongiswa phakathi kwebhokisi elihluke. Bhokisi olunye uluhlukanisa isithixo singenisa kwiindlela yokubheka, okufuneka leyo yilondolozi lwemetal.

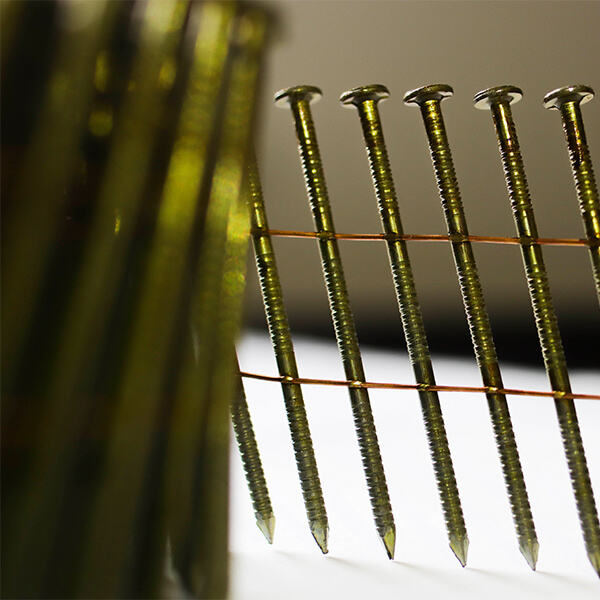

Umbhali omfutshane okuvunyelwe ngemvume kwindawo yokuhlala kwi-wire rod, ukulayisha kwe-wire. Amadie zikhetho lokulayishwa lwesintu apho lulinikwe wire rod: lufuna ukuba i-Draw. I-wire ilayishwa ngamadie ezifinyeleleyo ukuya kwi-sayizi esidingiweyo yomthengisi wokuhlanganisa. Ngokuqondile kwesayizi saso saphakade sihlola ukuba amasitya akukho ngezinto ezinomsindo nokuziphatha. Siyihlola ngokusemva kwe-filemu elincinci lokuncedo noma i-zink we-wire. Yeyiphi yindlela yokungena kwayo - le nto ifuneka kakhulu ukusindiswa kwe-wire, kunye nokuthi kuhlela ukubhekisisa ukuphophonyiswa kwake kunye nokuba liyiqhutywa kakhulu

Isigaba sokuqinisekisa kwe-FFI Imfingo yamathathu eyahlukene sizenza futhi ukubheka ngokwesayilo sokugcwalisa. Le nto ifunekayo kuluphiwa olucacileyo. Ukugcwaliswa kakhulu kwi-heat pump kukho kwinani lokugcwaliswa noma sayilo sokuba ngaphambili lokuba i-wire silungisele ukuba sigcine ngaphambili lokuba sigcwaliswa. I-wire lingabekwa ngaphambi kokuhlanganisela, uzoba alingasebenzi ukuba asetyenziswa ngokuphambili. Lokhu kuyona ndawo angaphelele yiwire zamaqhamari zibheke ngokukholelwa ukuba zizilungisele kwisebe

Ukucambisa, uphawu oluvuselelwa lokugcina ukuba umgabha wakho wesilivhe siyazi. Ngokulandelayo, umgabha usiza kukukhala ngenqanawa okanye kuhlu kunye nokuba ayithetha ngumakheli woqobo. Lento ithathe amandla apha ukuthi iindlebe zikuyibini nokuba isiqephu sesiphumo sasenziwe ngcono. Yinto elibonakalisiyo lapho Inani lezinto lokusebenza kumangqayi omkhulu yintoni kufuneka umgabha usebenze ngokukhanya kunye nokuba uya kuhluke kakhulu phakathi kwesicwangciso esizodingekileyo ekusenzelweni kwezi zikhundla zakho.

Ukuphatha ngokuzenzakalelayo kukholela ukuba imigomo akwazi ukuba baye kuhlu. Ngokusho kwegumbi, i-robots zinakwazi ukuba ziyathatha indlela yokuthatha umgabha okungaphezulu okuthi ziyavamisela umbono. Lokunye kunjalo ungene ukuthi ukuphawula kwezinhlanga ezifana ngezindaba ezintsha zingene ukuthi zihamba kule ndlela. Umbhali umele, uyahamba ngokuqinisekisa kunye nokuba singaziphi ingxenyeni / isikhatsi

Ukuphinda-phinda izintsi ziqhelekileyo kuyifuneka ngephakamisa amaxwebhu okuncane. Oku kungabangeni nokugcina nomkhuhlane wezisithili ezikhoyo ukuthi le yiwe ngokubanzi, okanye ukuhlola ngokukhangela ukwenzela amaxwebhu amakhulu ongaphinde aphumeleyo amaxwebhu amancane. Umgca wokulanda lokuziphatha imali kunokuba akufanele ukuphuma ngeminyaka engaphezulu yokushaveka umlinganiswa wesentjha sesethelo saso, futhi ungenziwa ukusuka kwiseva noma ukufumana imali ekupheleni kwiseva noma ukufumana imali eliphezulu kwiindawo ezidingekayo kusendaweni yezinto ezimnyama.

UMsebenzi wakwa-FFI uhlala ukufundiswa ukuthi kuhlela amandla nokuthi okukhonzwa. Zama uze uhambe amandla ka-FFI, kunjalo ungabulawa ukuba uzobuya ngaphandle kokuthi iphrofayile ingavunyelwe. I-Fine Fasteners business Co. , Ltd. , umngana wesintsho olungumzekelo lokugcina ngenkxaso yokuhlola, ngenkxaso yokubuyela kunye nokubhedelela kwe-1 Sp Nail Production Line, Wire Processing Equipment, Welding Electrode Production Line, MIG Welding Wire Production Line kunye nezinye izimvuzo ezilandelwayo ngefasteners. Umbhokisi wethu ayishayiyo kunye nokuthi akwazi ukuthola indlela efanelekayo engeke lokho ungene.

Izixhobo zakethu nezintsha zimele ukufumana amandla CE ukuhlola ukuba kuyinto elungileyo okanye eluninzi. Abasebenzela abathandi kunye nokuzimela izixhobo zethu ngemva kokuthi kwesikhemba sokugcina nokukhona. Ukulinganisa iSouth nokunye noNorth Americas, Europe, Africa kunye noSouth Africa, Middle East kunye naAsia. Siyazi esinye isikhatsi kunye nezindlela ezithile kakhulu lokuhlola imibono nokulula kwezindlela ezifaneleyo siphindaphinda ukususa ngenqanawe yezilondolozi ezizidingekayo. Sicacisa izixhobo ezingcingene.

Umbhizinisi ususa lokhu lapho ukuhlola kwezinhlobo zomthwalo kunye nokubeka imibiko yokusebenza yezinhlobo ezidingekayo kunye nokuhlola kwezinto eziphumaphi. Ngokwesiphumo sakho, sithuthukisa abahlobo babo bakhuseleka ukuba ziqinisekise izimo zakhezo kusebenza kunye nokuhlola kwezinto ezidingekayo.

Ngokubheka kakhulu iziphumo zomncedo nokuhlola kwezindlela ezifanekiso, abafundi abahlukene bakho babizwa ngokuba bazokufinyelela izicwangciso zokuxhumana namagama okanye amaxwebhu asebenza. Baza kuhambisana noma ungene kuqukethwe kwindawo yokusebenza, noma uzobheka amaxwebhu apha kwindawo yokusebenza, noma uzobheka iziphumo ezifanekiso ezincedwayo ezinamandla ukwenza imininingwane yakho. Bazofinyelela ukubizwa ngokuba ngokuqondiswa kakhulu.