Product Description

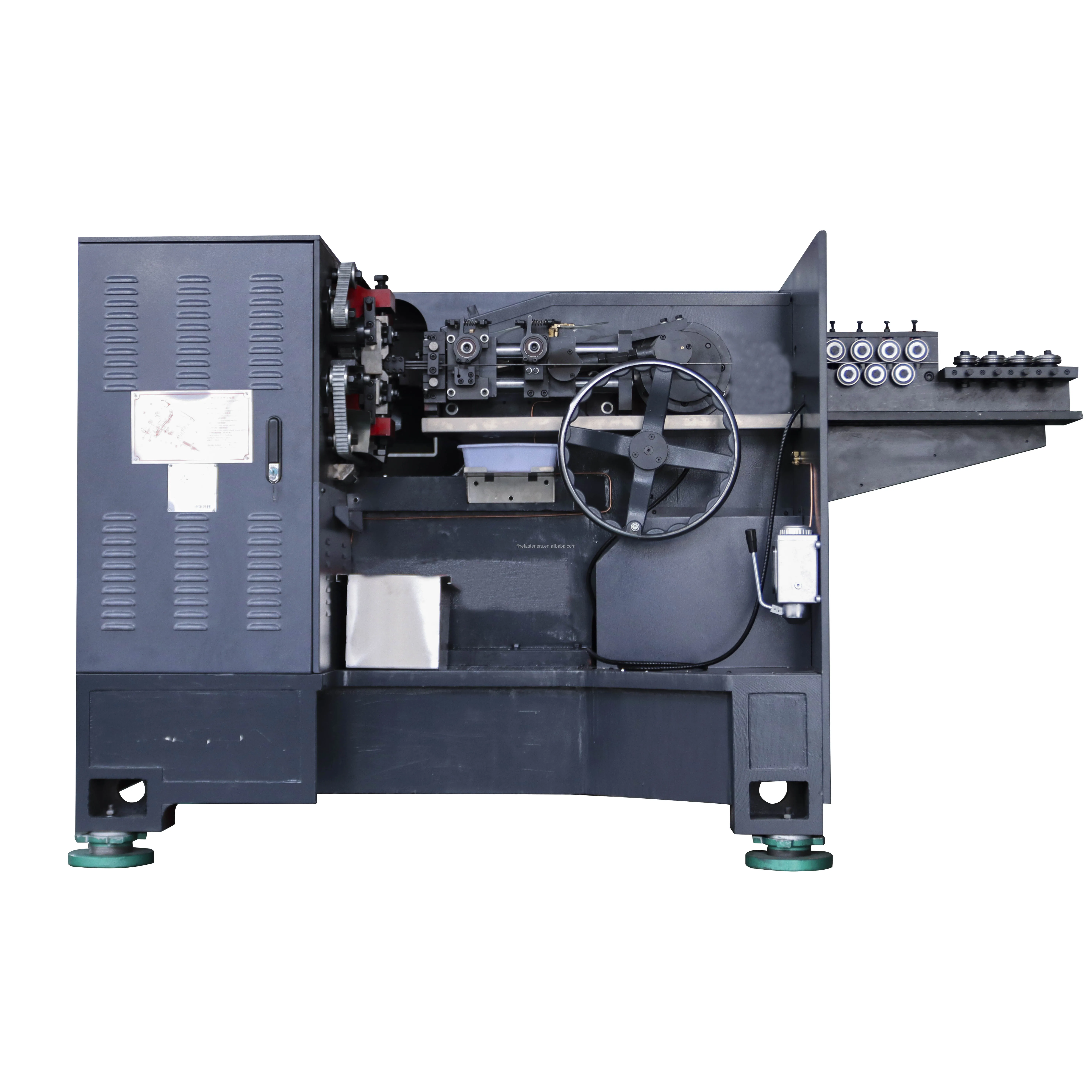

Long Service Life Plastic Sheet Nail Collating Machine Free Spare Parts

Product Description

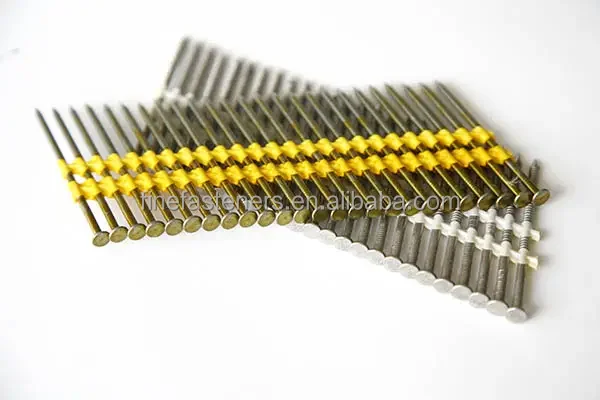

Plastic strip is generally used for 20° - 22° framing nails. They are held together by a strip of plastic that breaks apart when fired by a gun. They are less expensive than other types of collated fasteners (plastic coil or paper strip) because they are easier to manufacture.

Also can avoid deterioration due to weather conditions or high humidity

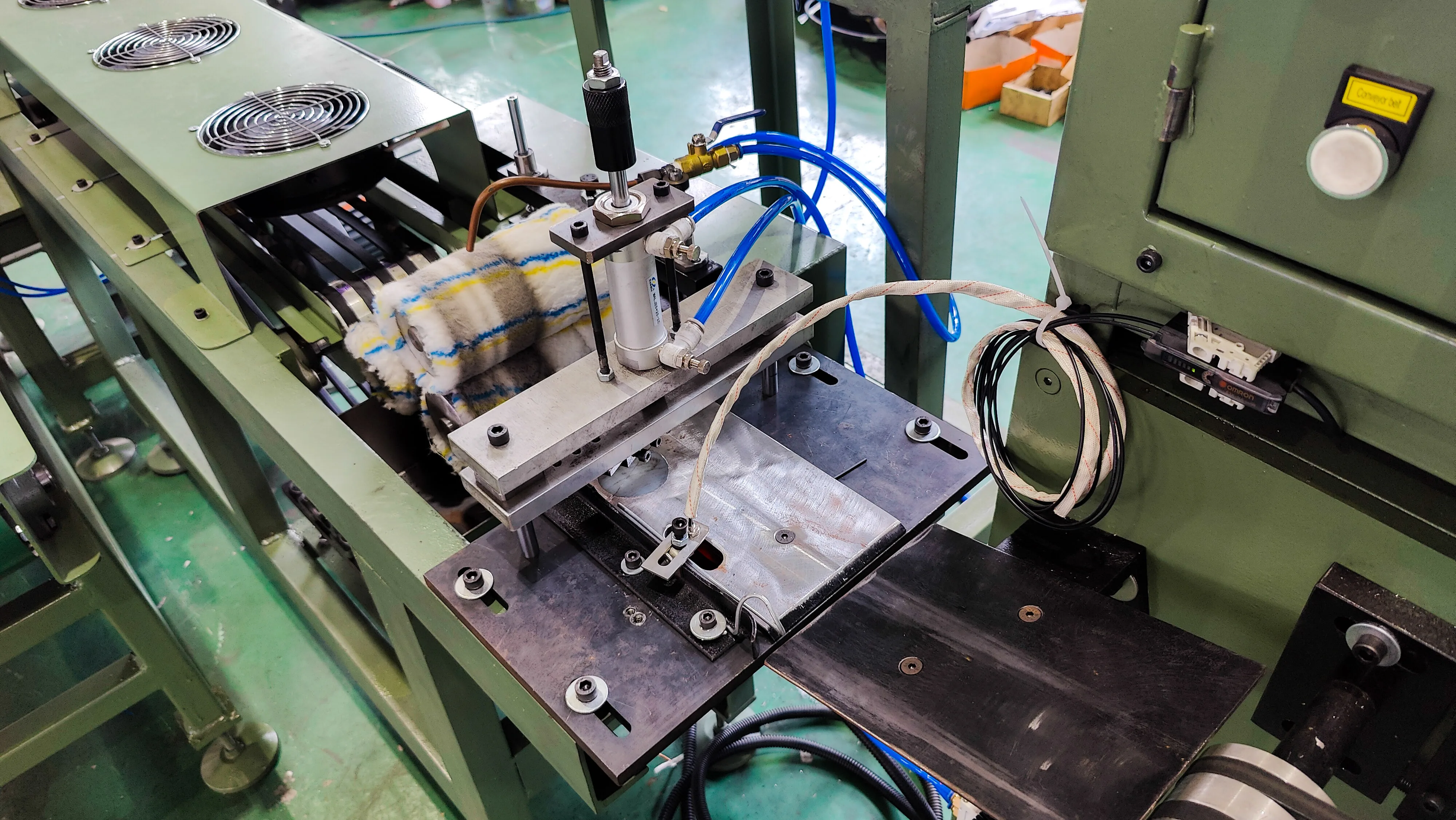

STACKER

Characteristics

It is well-designed and developed in our full-fledged production site by making the best use of pioneering tools and technology. Having equipped with the precision mechanical components and parts, this Industrial Plastic Strip Nail Machine ensures long service life. It is easy to operate the machine due to its user-friendly design and ergonomics.

The machine can produce bright, electro, hot dipped galvanized and stainless steel nails, with smooth shank, ring shank and screw shank.

-High collating efficiency -Minimum tooling changeover times -Closed cooling circuit for plastic moulding process -User-friendly design and ergonomics

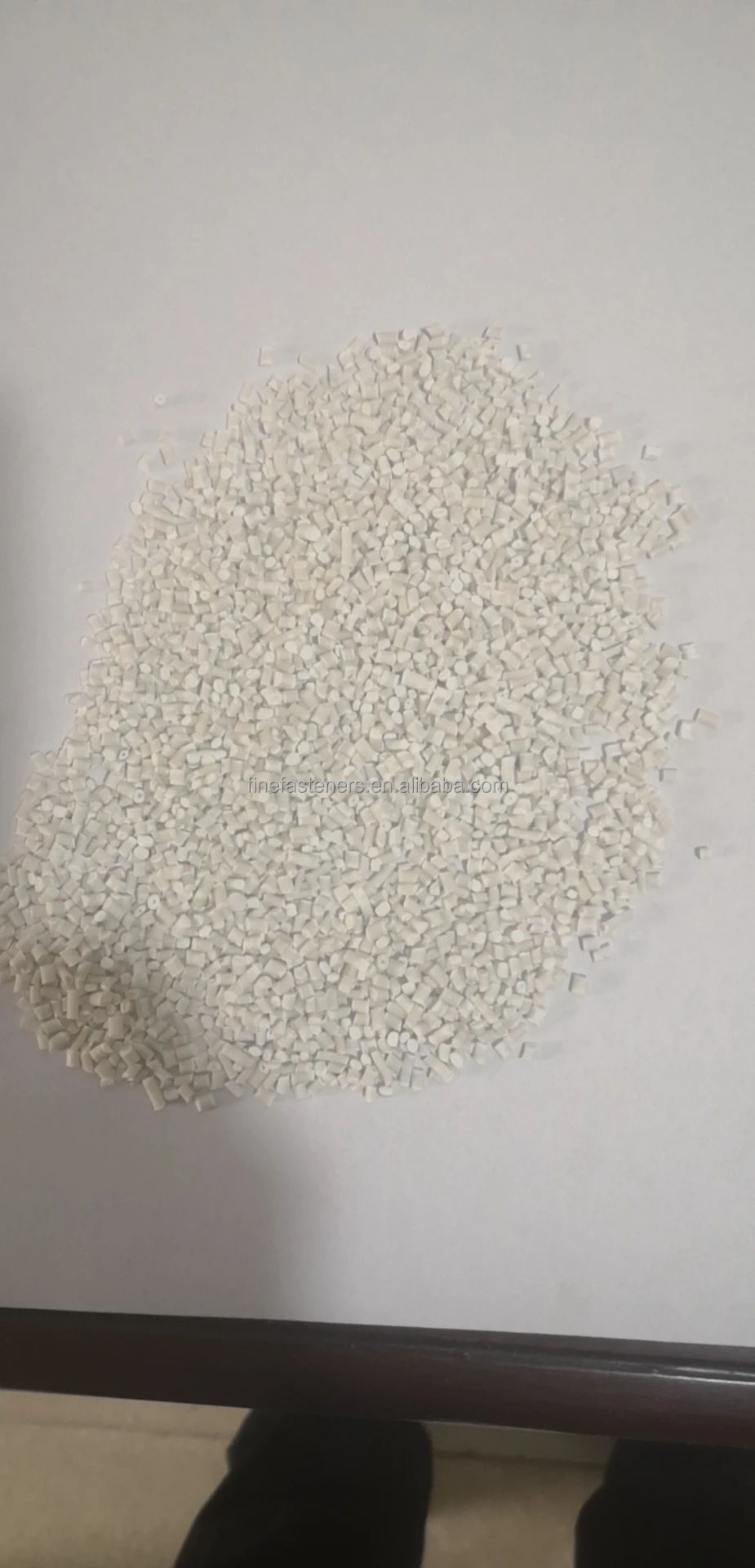

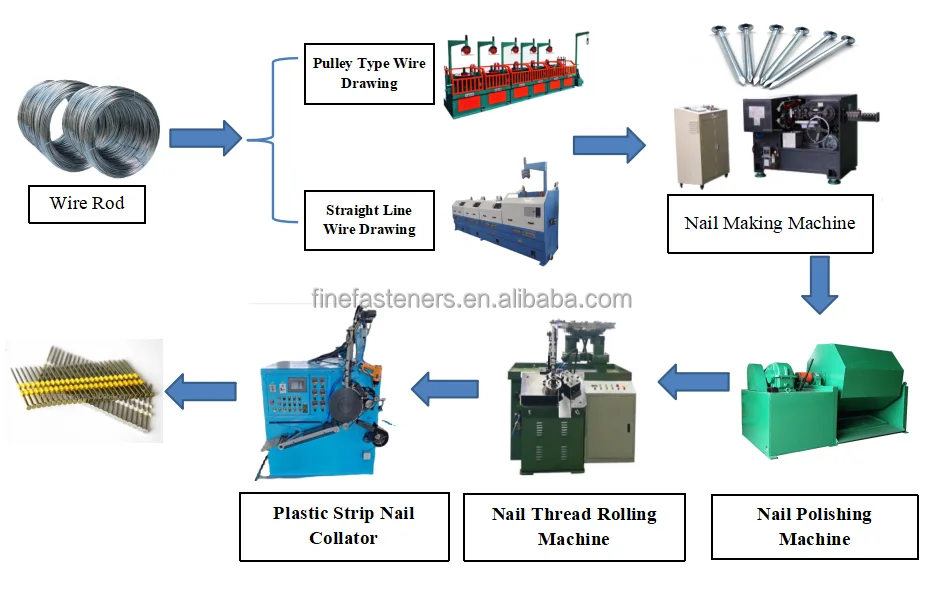

PP Granules Supply Chain:

Specification

Plas Strip Nail Making Machine/Collating Machine |

||

Nail making speed |

1200pcs/min |

|

Length of nails |

50-100mm |

|

Diameter of nails |

2.5-4.0mm |

|

Angle of nail |

21 degrees |

|

Hot melting temperature |

0-400 degrees |

|

Air pressure |

5 kg per cm2 |

|

Voltage |

380v,50hz or customized |

|

Machine Size |

L:2800MM*W:1800MM*H:2500MM |

|

Total weight |

1600kg |

|

Certifications

Packing & Delivery

Plywood carton with pallet

Company Profile

Fine Fasteners Industry Co.,Ltd (FFI) has been a super manufacturer and exporter of nails and the related machines such as all types of wire drawing machine, nail making machine, wire collating machine, plastic and paper tape machine, thread rolling machine.

Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions.

We have become a long-term partner for many nail making and wire making factories and helped a number of nail and wire making plants establish their own production lines in past years.

With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from

customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.

We are sincerely looking forward to working together with you to create a glorious future.

Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions.

We have become a long-term partner for many nail making and wire making factories and helped a number of nail and wire making plants establish their own production lines in past years.

With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from

customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.

We are sincerely looking forward to working together with you to create a glorious future.

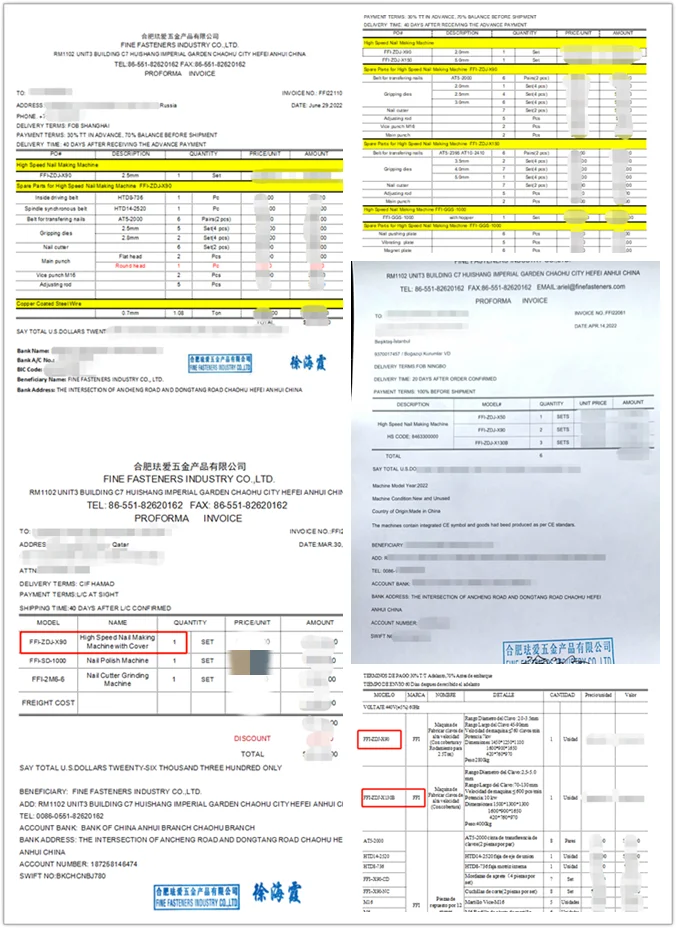

Customer Photos

ORDERS

FAQ

1. Time for changing nail sizes ---->

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be

changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local

accommodation should be paid by your company. Engineer service charge is US$100/day

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be

changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local

accommodation should be paid by your company. Engineer service charge is US$100/day

EN

EN