Product Description

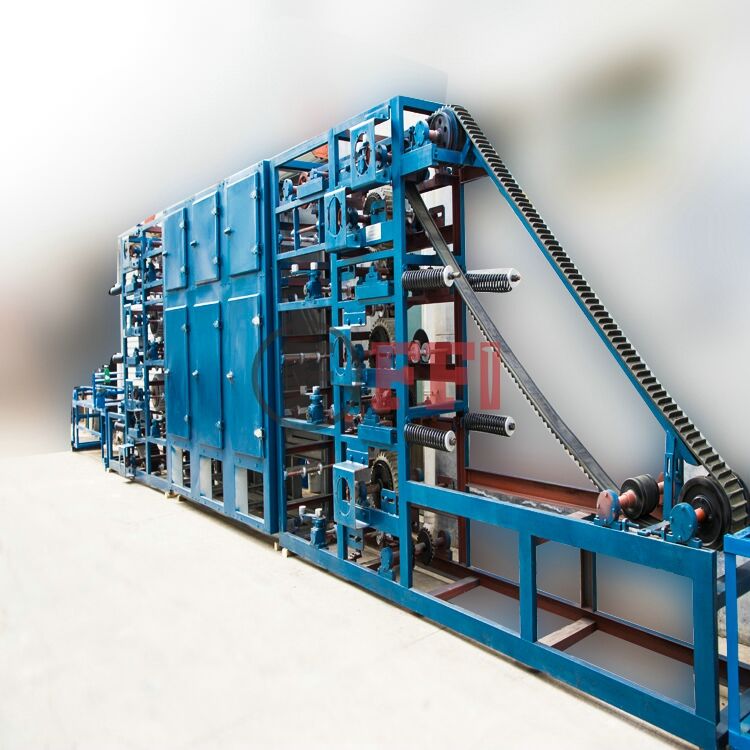

The FFI Customize Capacity Machine Welding Rod Making is a product this is certainly top-of-the-line can appeal to your entire welding rod-making needs. Designed to withstand use this is certainly hefty final for many years, this product is wonderful for welding enthusiasts and experts alike.

Featuring its capacity this is certainly customizable can now make welding rods of numerous sizes and lengths with ease. This particular feature really helps to make sure your welding tasks must not be restricted to how welding that is big available in the market. It is possible to produce welding rods particular to virtually any project's demands, that could further enhance its effectiveness and quality.

The FFI Customize Capacity Machine Welding Rod Making can be simple to also run, meaning that you don't have to be a specialist to utilize it. With only a few actions being simple you could make welding rods of any ability, additionally the device will immediately adjust its settings to make the rods you will need.

This machine can also be very durable and can withstand environments which are diverse. It really is crafted from top-quality materials that may withstand materials which is often steel that is harsh plus it produces a finished welding rod that is neat and ready for use. FFI Ensure that most their products or services or services are durable and regarding the high quality that is greatest, making sure you have the absolute most from the opportunities.

FFI Customize Capacity Machine Welding Rod Making is also very economical, making this available to both welding enthusiasts and welders being expert. This machine can help you save money in the run that is long as you not any longer need certainly to buy costly ready-made welding rods featuring its effectiveness and durability.

The FFI Customize Capacity Machine Welding Rod Making is very easy to clean and operate with regards to of upkeep. You'll quickly clean it by wiping it straight down with a fabric that is dry and it is sold with a person manual which could show you through all of the maintenance needs.

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

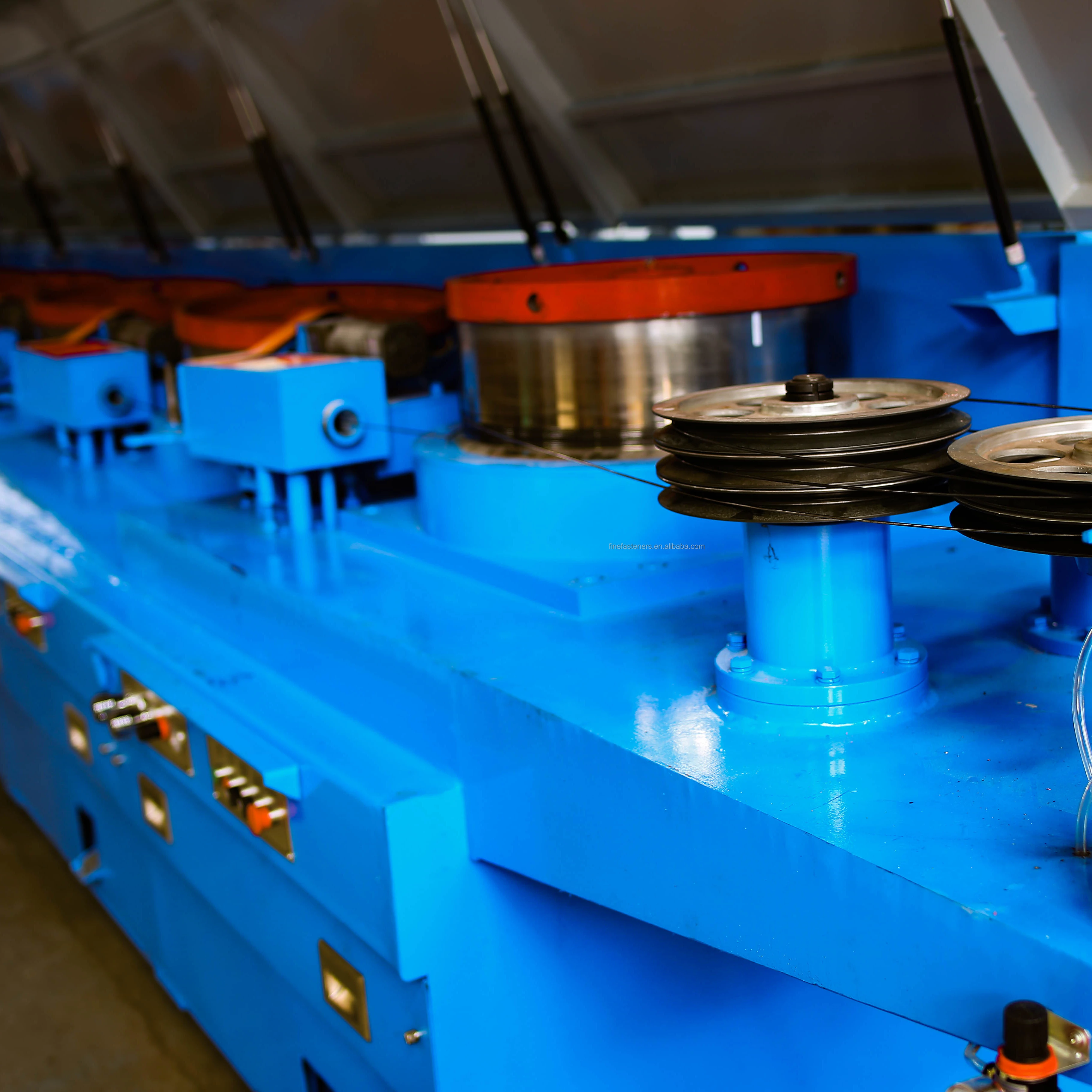

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

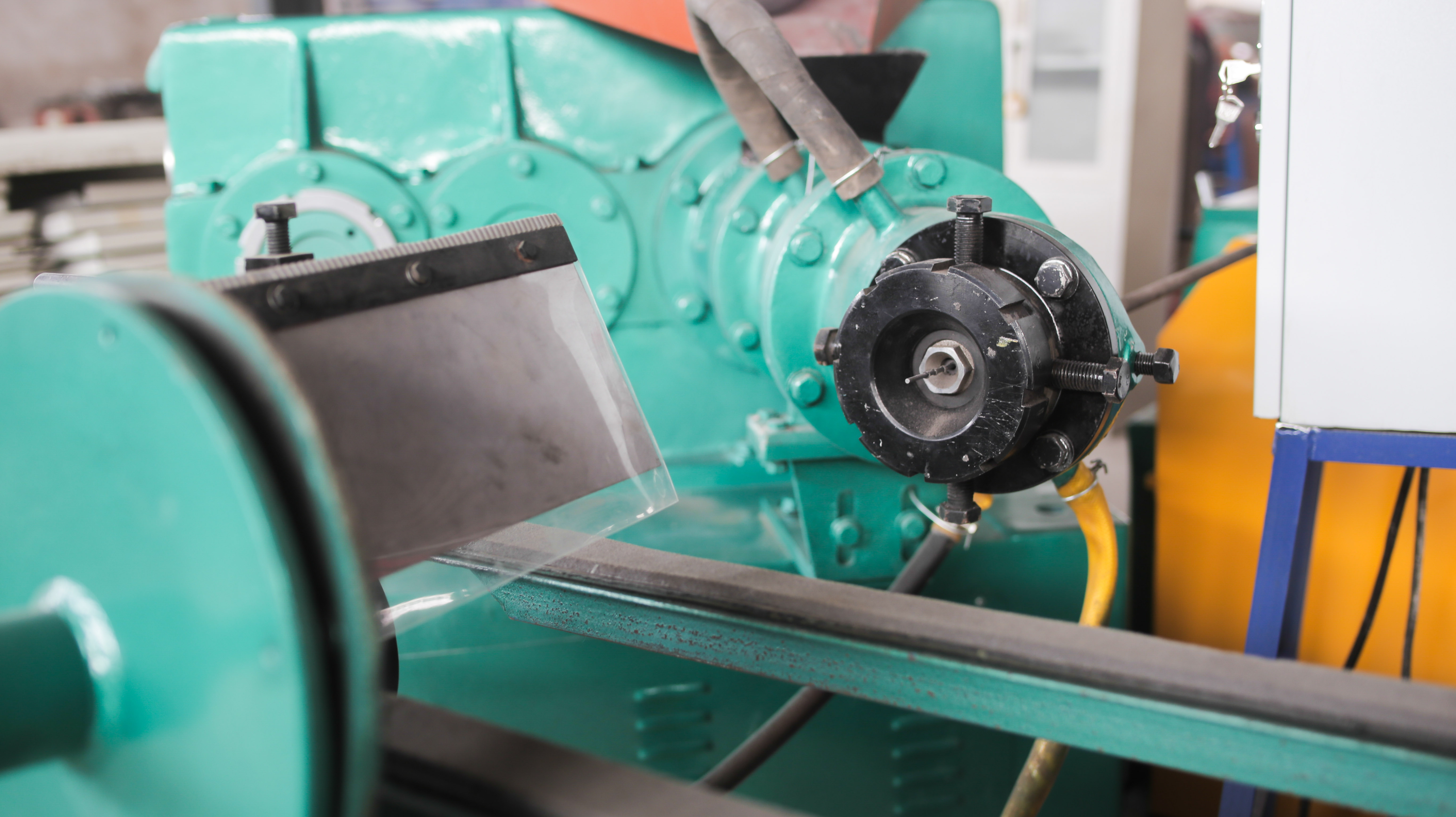

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN